Konvaor

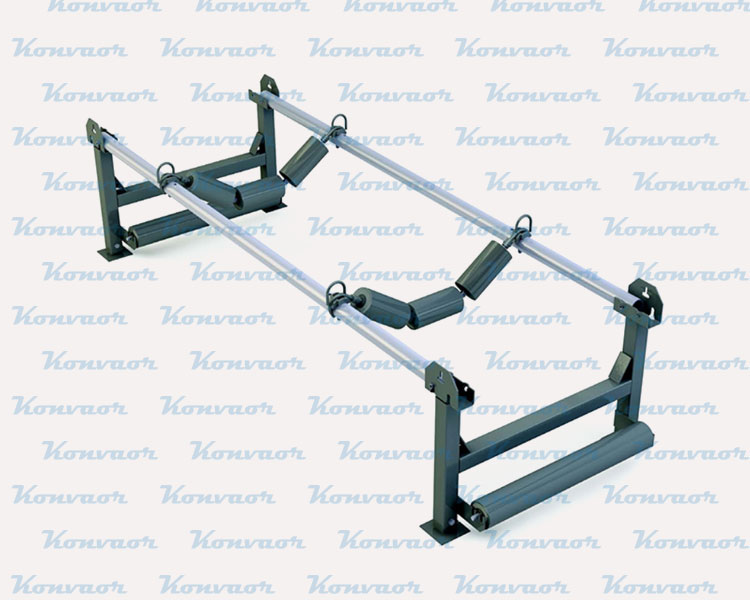

IDLERS In summary, the four most commonly used types of idlers are trough idlers, flat return idlers, impact idlers and training return idlers.

They support the belt and conveyed material along its full length preventing it from stretching, sagging and eventually failing. Conveyor rollers and idlers are often required to operate in harsh environments such as dirty, dusty, high humidity, and drastically high or low temperatures.

Type

- Rubber Idlers

- Ceramic Idler

- Nylon Idlers

- Insulated Idlers

Material

- Steel covered in Rubber

- Steel with Ceramic tiles or fully Ceramic

- Nylon (Type of Plastic)

- Various insulating materials

DUST SEALS This is a rubber dust seal with double lip to prevent oil spilling. Nitrile rubber and fluorine rubber are available, so it can be used in a wide range of temperature conditions. Prevents dust from entering from the outside to protect packings and bearings.

Dust seal covers, or boots, are accordion-like rubber or plastic seals designed to keep dust out of the systems they protect. Dust seals are found on a variety of systems from brake calipers to the power steering system. They may protect shaft joints, ball studs, or steering linkages.

Circlips are typically made from stainless steel and similar metals. Alternative names for circlips include retaining rings, retaining clips, C-type, Jesus clips, snap rings, and E-type. Retaining rings serve as a removable shoulder within an assembly to retain components in a bore or on a shaft.

Circlips are used to prevent lateral movement. They are used as retaining rings on bearing assemblies and are manufactured using semi-flexible metal ring. These products are in a shape of a circle with a clip and are open from one end. The most common form of axially fitted circlips for shafts with grooves.

There are two basic types of circlips: internal (fitted into a bore) and external (fitted over a shaft). Circlips are often used to secure pinned connections.

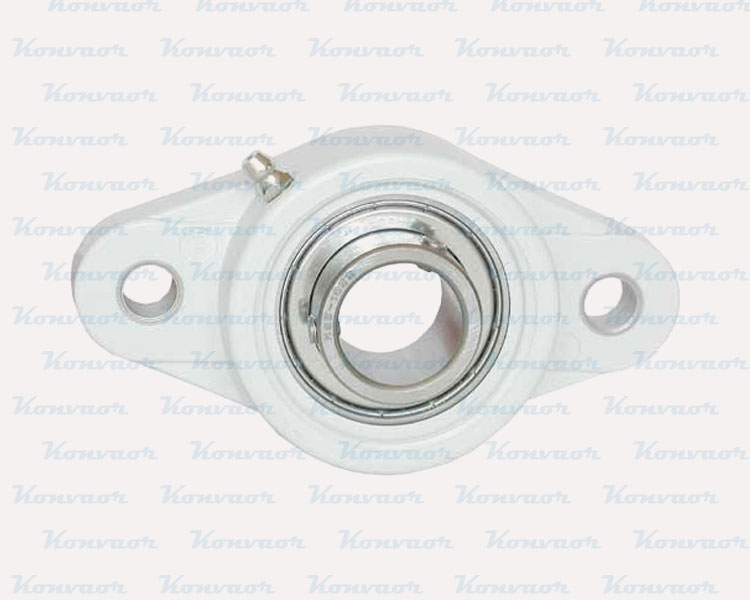

Thermoplastic Bearing Units are corrosion resistant units for various applications and are needed for the environments of clean operating. Thermoplastic bearing units provide the desirable thermal, electrical and mechanical properties that offer the standard products.

Bearings are “parts that assist objects’ rotation”. They support the shaft that rotates inside the machinery. Machines that use bearings include automobiles, airplanes, electric generators and so on.